Streamlining PCBA Testing: A Comprehensive Guide by Maker-ray

In today’s fast-paced technological landscape, the seamless functionality of printed circuit board assemblies (PCBAs) is paramount. To ensure optimal performance and reliability, thorough PCBA testing is crucial. In this article, we will delve into the significance of PCBA testing, explore its various methodologies, and highlight how Maker-ray, a renowned industry leader, offers innovative solutions in this domain.

The Importance of PCBA Testing Efficient

PCBA testing plays a vital role in guaranteeing product quality and customer satisfaction. By meticulously examining the functionality and integrity of each component on a PCB, potential defects or anomalies can be identified early on, mitigating risks and reducing costly rework. Moreover, thorough testing ensures compliance with industry standards, regulations, and best practices.

Exploring PCBA Testing Methodologies

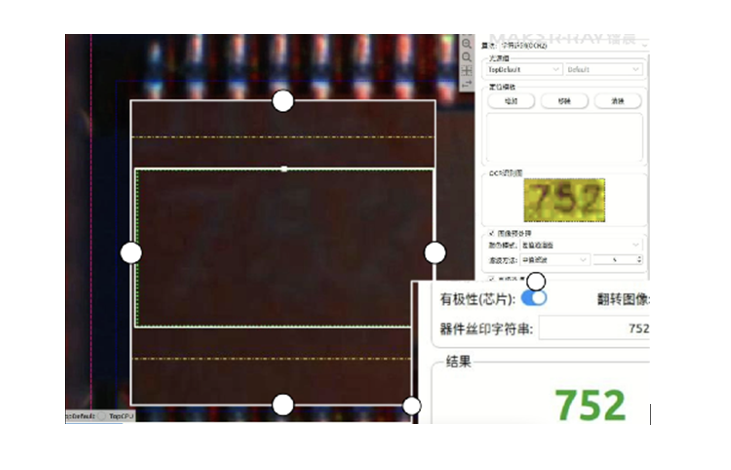

Functional Testing: Functionality is the core aspect of any PCBA. This testing methodology validates whether the assembled board operates as intended, confirming that all components interact harmoniously. Maker-ray deploys advanced functional testing techniques, including boundary scan, in-circuit testing (ICT), and custom test fixtures tailored to specific project requirements.

Environmental Testing: To assess a PCBA’s resilience under varying conditions, environmental testing is conducted. Maker-ray employs environmental chambers capable of subjecting PCBAs to extreme temperatures, humidity, and vibrations. These tests simulate real-world scenarios, enabling accurate evaluation of the board’s performance in challenging environments.

The Maker-ray Advantage for PCBA Testing

Customized Testing Solutions: Understanding that every PCBA project is unique, Maker-ray tailors their testing methodologies to align with specific client requirements. This customized approach maximizes efficiency and ensures comprehensive coverage of critical aspects.

Domain Expertise: With years of experience in the industry, Maker-ray boasts a team of highly skilled engineers and technicians. Their expertise spans across various sectors, enabling them to handle complex PCBA testing challenges effectively. More on this topic can be found at isaimini blog.

Conclusion

In the realm of PCBA testing, Maker-ray stands as a trusted partner, offering cutting-edge solutions tailored to the unique needs of each client. By prioritizing quality, accuracy, and efficiency, Maker-ray streamlines the testing process, empowering businesses to deliver robust and reliable electronic products. With their unwavering commitment to excellence, Maker-ray continues to drive innovation in the field of PCBA testing.