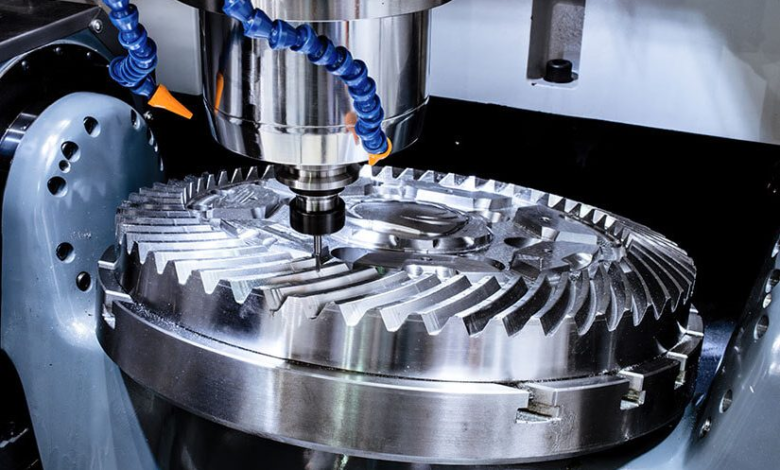

A New Era for CNC Milling Technology

Have you heard about the newest style of milling technology? This article is for you if you’re planning on buying a new CNC mill. In this blog post, you’ll find out what to do before buying a CNC mill and how hot the industry is turning.

Introduction

CNC milling technology was used for small production runs and specialized applications in the past. However, with the advent of 3D printing and other additive manufacturing technologies, CNC milling is now becoming more mainstream. This is because CNC milling can produce products with high precision, speed, and accuracy.

One of the most significant benefits of using CNC milling technology is that it can produce parts with great flexibility and detail. This is because CNC milling can create pieces from a variety of materials using a variety of processes. Additionally, CNC milling is capable of producing highly complex shapes and structures.

As a result of these factors, many companies are beginning to use CNC milling technology in their product development process. This is because it allows them to produce products with far greater accuracy and flexibility than traditional methods. In addition,3D printing has made it possible to create custom parts quickly and inexpensively – making CNC milling an even more attractive option for businesses seeking high-quality products at low costs.

CNC milling is making parts from a solid block of material by directing a precision cut on a machine that typically uses an oscillating cutting tool.

Types of CNC Milling Machines

There are a few different types of CNC milling machines on the market, and each has its advantages and disadvantages. Here is a breakdown of the most common types:

- Computer Numeric Controlled (CNC) Milling Machines: These machines typically use a computer to control the movement of the cutting tools, which allows for precise cuts that are repeatable and accurate. They are usually more expensive than manual mills, but they can produce high-quality parts much faster.

- Manual Milling Machines: Manual mills use a movable tool head to make cuts on the material using a hand-held operation. They are cheaper than CNC mills and can be used for smaller parts or simple shapes, but they offer less precision or accuracy. They also tend to be slower than CNC machines.

- Dual-Axis Milling Machines: These machines have two axes that move in opposite directions, improving the accuracy and precision of the cuts. They can be more expensive than single-axis machines, but they’re versatile and can be used for more complex parts.

Benefits of CNC Milling Technology

CNC milling technology offers many benefits that can make your manufacturing process more efficient and accurate. Here are four of the most notable:

- Reduced Tooling Costs

- Increased Efficiency

- Improved Quality Control

- Reduced Production Timeframes

Conclusion

Thank you for reading! In this article, we will discuss the latest and greatest in CNC milling technology– what it is, how it works, and some of its benefits. We hope that this information has helped you decide whether or not CNC milling is suitable for your project and, if so, which machine would be best suited for the task. Thanks again for reading! If you want to find CNC milling service, please contact with KAIAO, a professional rapid prototyping manufacturer!

Samsclub provides a one-stop shopping experience, offering a wide range of products at affordable prices. With its membership benefits and convenient online platform, customers can easily access quality goods and save both time and money. Whether you’re stocking up for your home or business, Samsclub is the go-to destination for all your shopping needs.